565 Milwaukee Ave., Suite 3B

Burlington, WI 53105

Phone: 262-827-9575

565 Milwaukee Ave., Suite 3B

Burlington, WI 53105

Phone: 262-827-9575

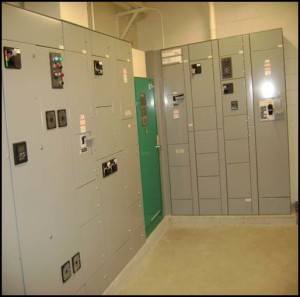

The new $6,000,000 water treatment plants electrical design included a 1,600 amp, 277/480 volt electrical service, automatic transfer switch, 650kw diesel generator, three motor control centers (mcc-1a, mcc-1b and mcc-2). mcc-1a, ats-1 and mcc-1b were located in the electrical equipment room with mcc-2 located in the pipe room.

the equipment loads included a 100hp deep submersible well pump, 75hp high service pumps, backwash filter pumps, all operating on vfd’s, power distribution panels and chemical systems. the design included the instrumentation and control system that consisted of a main control panel cp-1 located adjacent the mcc-2 line up with the filter control panel located on the mezzanine level near the filters. in addition, a fire alarm system, security system, scada panel for remote monitoring and control and provisions for future cameras were included.

BUILDING EXTERIOR |

MCC-1A, ATS-1 AND MCC-1B |

CP-1 |

MCC-2 & GENERATOR |

We provided design services to Indian Health Services (IHS) for the Lac du Flambeau main and west well pump station designs. The project design included converting 120/240 volt single phase power to 240/480 volt single phase power to operate 480 volt three (3) 15 hp three phase well pumps on vfd units that were located as far as 245 feet from the building at the west well pump station and we utilized 277/480 three phase power to operate 480 volt three (3) 5 hp three phase well pumps on FVNR starters located at the main pump station building.

The designs also included exterior mounted generators, motor control centers MCC-1A, MCC-1B, control panel SP-1 and automatic transfer switches located at each facility. Integration of SCADA controls were also provided to operate the various chemical pumps, flow meters, pressure transducers, pressure switches, flow switches, weight scales and intrusion switches and to monitor and control the motor controls. We also provided Indian Health Services with assistance their interior building lighting, exterior building lighting and the heating and ventilation systems.

WEST PUMP STATION EXTERIOR, MAIN PUMP STATION EXTERIOR SIMILAR. |

ATS-1, MCC-1A & MCC-1B EQUIPMENT LINE UP AT THE WEST PUMP BUILDING. |

MCC-1A, ATS-1 & MCC-1B EQUIPMENT LINE UP AT THE MAIN PUMP BUILDING |

THE EXTERIOR MOUNTED GENERATOR |

The new $9,000,000, 7 MGD water treatment plant with separate well building expandable to 13 MGD included a 3000 amp, 277/480 volt electrical service, 3000 amp automatic transfer switch and 3000 amp distribution switchboard and separate generator control panel for monitoring and controlling up to seven 400 kw generators to accomadate the full expansion. The electrical design included MCC-1, MCC-2, MCC-3 and provisions for MCC-4. The main distribution equipment, ATS, generators and generator controls were designed as a packaged system between Kohler and Cutler Hammer.

The PLC control system consisted of main control panel CP-1, remote control panel CP-2, filter control panel CP-3, remote control panel CP-4 and SCADA control panel for remote communications and desktop PC operating wonderware software. Other control panels integrated into the process control included the UV control panels, polyphosphate, sodium permanganate and fluoride control panels and chemical rooms lighting and exhaust systems.

BUILDING EXTERIOR |

|

MAIN PLC CONTROL PANEL CP-1 |

GENERATOR ROOM WITH FOUR 400 KW NATURAL GAS GENERATORS WITH FUTURE EXPANSION TO SEVEN GENERATORS |